CNC Programming, Prototypes, and Production

Modern manufacturing demands a precise balance between design intent and production constraints. I have extensive experience bridging that gap, having overseen in-house and overseas manufacturing for my brand’s products, produced in the U.S. and China. Success in this arena requires constant, clear, and detail-oriented communication with suppliers and teams across time zones and cultures.

My manufacturing journey began with a Bridgeport milling machine I converted to CNC. I became proficient in Mastercam and later transitioned to SolidCAM. Over the years, I expanded operations to include four VMC CNC machines with robotic loading systems, running 12 to 24 hours a day, and eventually scaled production overseas.

My experience includes:

CNC Programming & Operation

Programming with SolidCAM

Running, purchasing, and maintaining CNC mills with robotic loaders

Expert in high-speed, adaptive machining and achieving precision tolerances and fine surface finishes

Experience across a wide range of machine types; I’ve also built custom CNC systems from scratch

Production Management

Designing and implementing complex fixtures for high-volume production

Training and managing CNC operators

Setting up and overseeing full in-house production lines—from raw material cutting (metal, wood, composites) to finishing, assembly, and packaging

Outsourced Manufacturing & Supply Chain Coordination

Developing comprehensive design packages for external manufacturers, including specifications, materials, surface finishes, tolerances, and techniques

Managing QC teams to ensure all products meet spec and brand expectations

Coordinating with international legal teams to navigate shipping, documentation, and compliance for complex projects

Building long-term, mutually beneficial relationships with overseas partners by bridging cultural and language differences

Deep familiarity with Chinese production capabilities and communication protocols

27 Axis robot that simulates a beer bottle breaking. All parts desinged and machined in house.

Staubli RX60 Robot integrated with Fanuc Robodrill which could run 20 hours unmanned.

Adaptive Machining on a Fanuc Robodrill

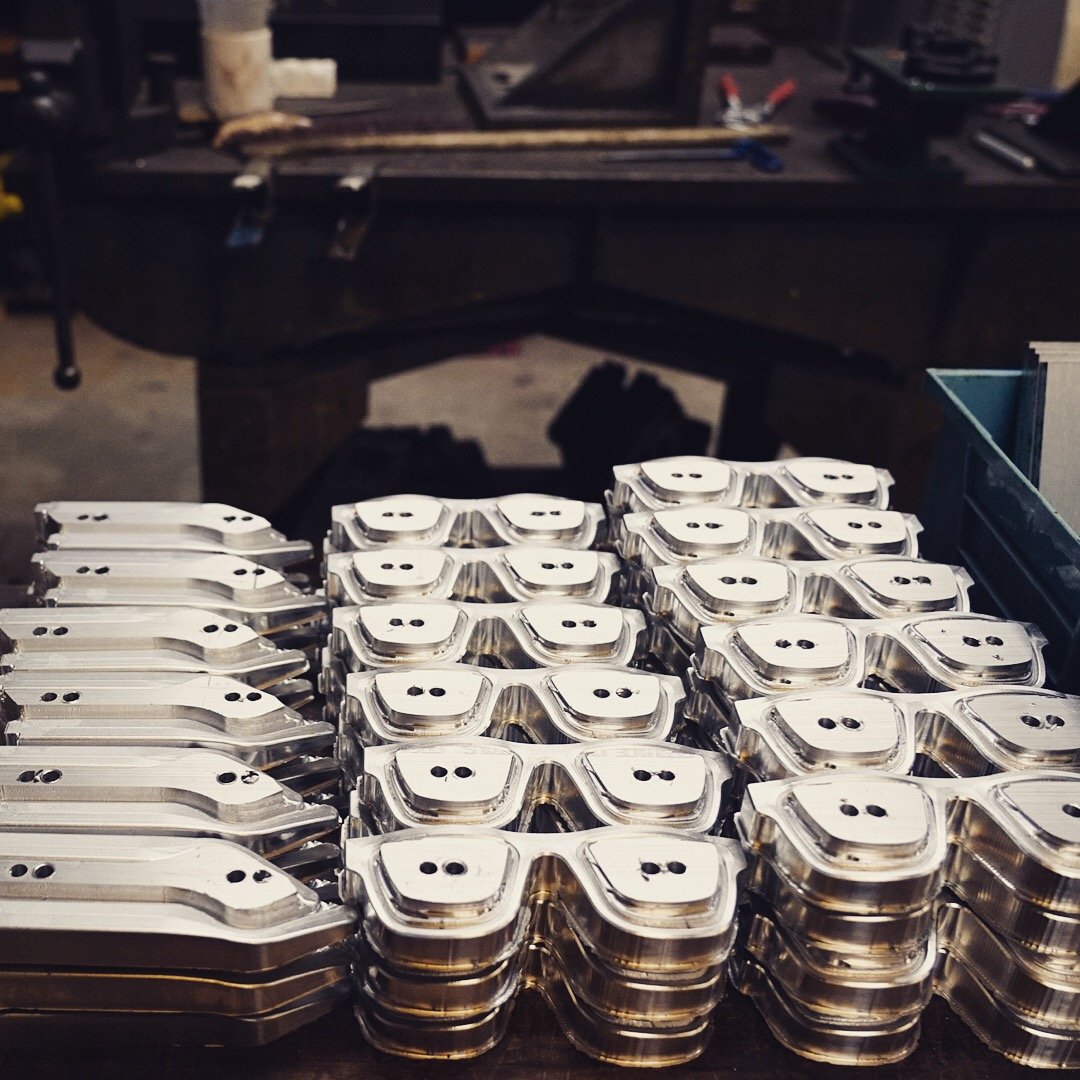

High speed maching the Inside of Kingsland Glasses being cut on Fanuc Robodrill

3d printer nozel desinged to print salt.

Kingsland frames ready for first step.

Beautiful Kingsland Frames just off the machine.

Exquisite machined prototype components for a computer mouse.

Elegant machined beauty.

Machined Titanium Case combined with a CNC cut FRP and hardwood composite.

Programming one of our CNC VMCs.

Kingsland frames machined from solid.

Thousands of the most beautiful mouse ever made. Details