Production - CNC progaming

To produce objects in this modern world it is an exacting balance of design goals and production reality. Our EXOvault objects were produced in-house here, in the United States, and in China. It takes vigilant, constant, and clear communication to work with outside suppliers.

We started manufacturing with a Bridgeport milling machine I converted to CNC. I soon became proficient in CAM using Mastercam and moved to Solidcam. Over the years we graduated to four CNC machines with robotic loading running 12 to 24 hours a day. I also moved and managed production overseas.

I understand and have experience in the following areas:

Setting up and running CNC milling machines with robotics

Programming CNC machines using Solidcam and MasterCam

Expert at superior machining operations including adaptive and high-speed machining

Experience achieving superior finishes and tolerances.

Experienced with many machine types including Fanuc and many others. I have built CNC machines from scratch

Experienced with complex production fixturing.

Training CNC operators

Setting up and managing in-house production including

Cutting of metals wood and composites

Finishing

Assembly

Packaging

The process of making design packages that outline specifications, textures, materials, tolerances, and production techniques for outside production.

Managing product control specialists to confirm every product is within specifications and meets expectations.

Communicating with international lawyers in China and other countries to find solutions and ship difficult projects through a myriad of international touchpoints.

Anticipating and solving issues that stem from cultural and language divides making for a mutually beneficial partnership.

Understanding Chinese production capabilities, practices, and communication intricacies.

Staubli RX60 Robot integrated with Fanuc Robodrill which could run 20 hours unmanned.

Adaptive Machining on a Fanuc Robodrill

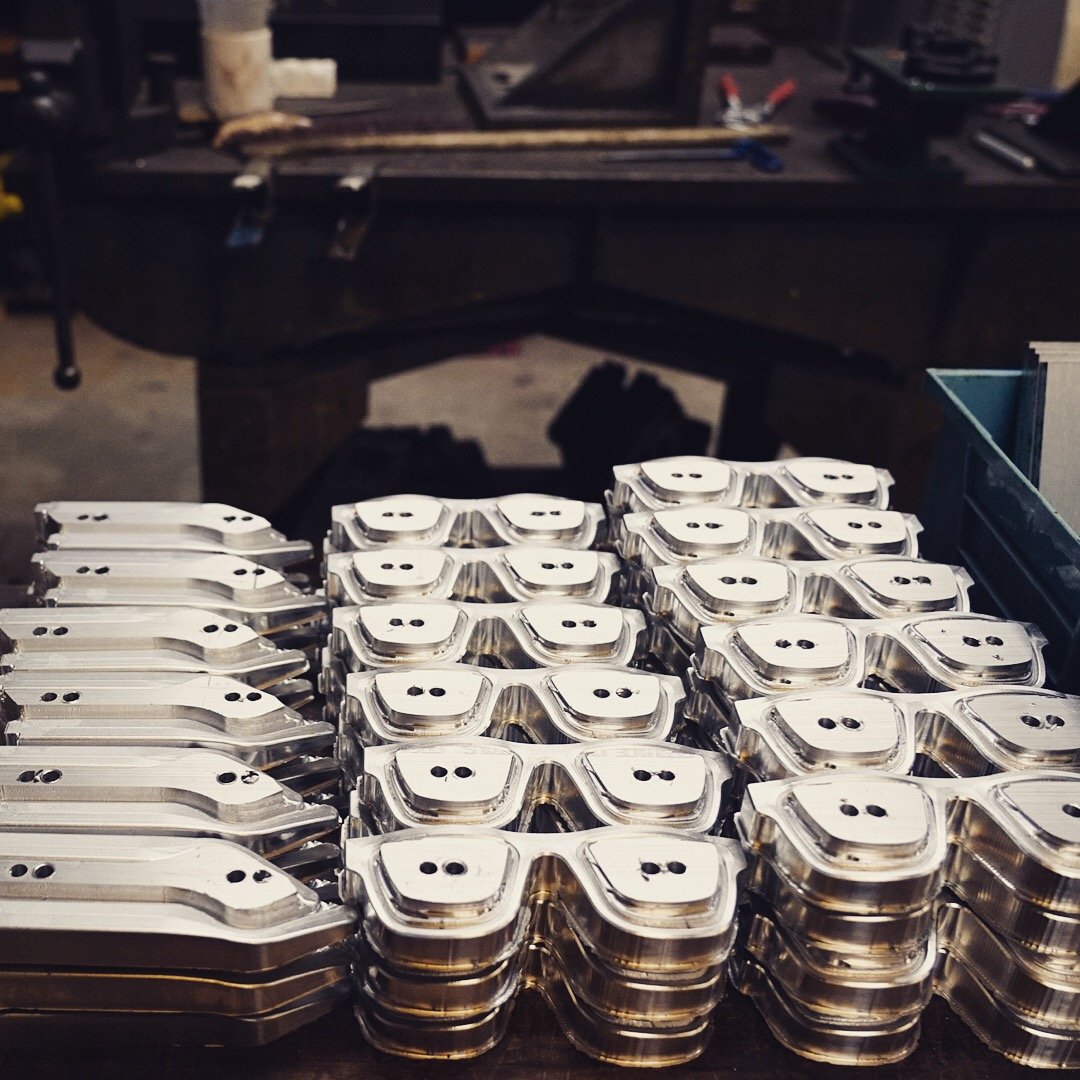

High speed maching the Inside of Kingsland Glasses being cut on Fanuc Robodrill

Kingsland frames ready for first step.

Beautiful Kingsland Frames just off the machine.

Exquisite machined prototype components for a computer mouse.

Elegant machined beauty.

Machined Titanium Case combined with a CNC cut FRP and hardwood composite.

Programming one of our CNC VMCs.

RFQ For Kingsland Frames offshore production. Download PDF

I produced in China thousands of the most beautiful mouse ever made. Details